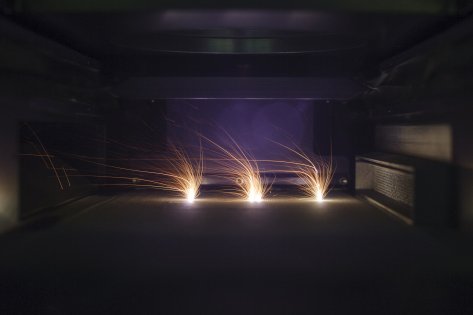

Optimized Powder Bed Laser Melting processes

The goal of Aconity3D GmbH is to optimize the stability of an innovative manufacturing method called Powder Bed Laser Melting and to promote its use in a wide range of industries. By utilizing high-speed industrial cameras from SVS-Vistek, the company has come one step closer to this goal.